Many water treatment systems in horticulture employ only a “barrier” approach to water treatment. This is an approach that uses a barrier, physical or chemical, to remove pathogens and particulate at one point in the water stream, preventing contaminants from entering the irrigation system. Filtration systems, heat-pasturization and ultra-violet sanitation systems all employ a barrier to eliminate or prevent contaminants from moving down stream of the barrier. This method may remove undesirable components in your water, but they do not provide any residual sanitation in the plumbing and other equipment downstream and they do nothing to help promote the health of the crop.

A more holistic approach can satisfy each of these demands: eliminating pathogens and particulate, eradicating biofilm and the pathogen inoculum that lives in the plumbing and providing healthy, oxygen-rich water to help build stress-free plants.

In a holistic water treatment system, single barriers or equipment are often part of the solution. However, very rarely will one component be enough to treat the water in a facility. Normally, these are coupled with a sanitizer to provide additional pathogen removal and possibly some residual benefits. Physical barriers, such as media filters and ultrafiltration can remove much of the contamination in the water. This reduces the amount of sanitizer needed post-filtration. There are a number of chemical oxidizers or sanitizers that are sometimes used post-filtration. Hydrogen peroxide, peroxyacetic acid, hypochlorous acid, sodium hypochlorite, chlorine dioxide and ozone. Only ozone sanitizes while providing oxygen to the plants.

Ozone, or triatomic oxygen, is the strongest oxidizer available for commercial use. It is the best product for eliminating both pathogens and biofilms in the plumbing. It is extremely reactive, ensuring that it works quickly and degrades to dissolved O2 in the water.

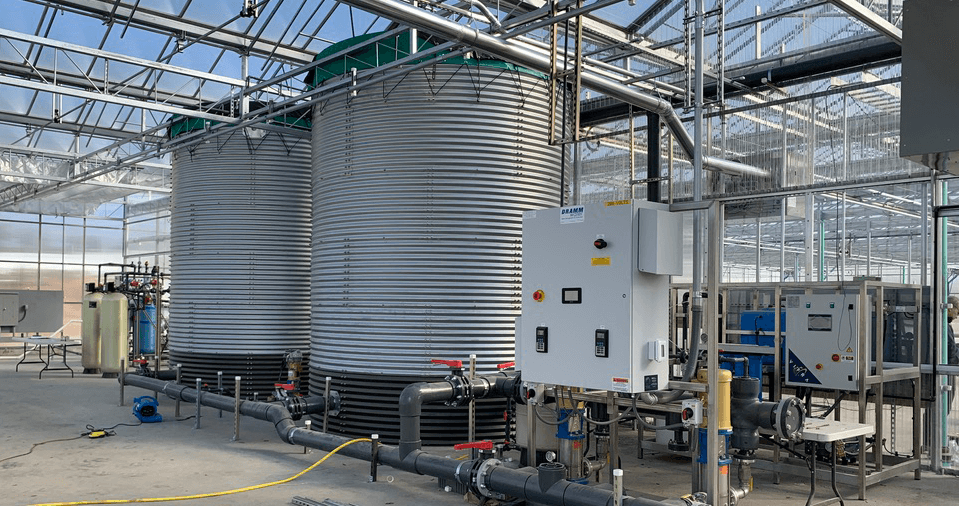

In a DRAMMwater system, filtration is used to remove larger contaminants before the water is treated with ozone. This barrier allows us to remove any larger particulate or oxidants that would require more ozone capacity to eliminate. Systems are designed to provide optimal contact time and to recirculate the water through the treatment system into a storage tank to increase the ORP (oxidation reduction potential) of the water and create super-saturated levels of dissolved oxygen.

Unlike a barrier-only system, the ozone provides a residual to attack biofilm in the plumbing and provide additional pathogen control throughout the system.

However, another important factor with ozone is the holistic benefit. Not only are the water and the plumbing systems sanitized, the sanitizer reverts to high levels of dissolved oxygen (DO) after oxidation. This super-saturated DO has plant health benefits, promoting strong root growth and creating an aerobic environment in the rhizosphere that aides beneficial microbial activity while creating an antagonistic environment for most plant pathogens. In general, this creates a stronger, less stressed plant.

This benefit will help improve the crop’s ability to survive stresses from the environment or from external pathogen sources, improving plant quality over time. The high DO will also help to improve plant growth, often reducing crop time or increasing yield. Often faster rooting, quicker turns and increased fruiting and flower count are the result of super-saturated dissolved oxygen.

There are a number of oxygen supplementation systems in the market today. While adding oxygen is a good thing, because O2 alone is not a strong oxidizer, these systems have little impact on pathogens and biofilm. Initially, oxygen levels increase as high DO is introduced into the system. The anaerobic biofilms that exist in the plumbing will be reduced and oxygen will increased to the plants. Unfortunately, this benefit is reduced over time as aerobic biofilms replace the anaerobic biofilms without the sanitizing benefit. As these grow, they will use much of the added oxygen that the plants initially saw, reducing the availability of DO to the crop.

Only by utilizing a complete system approach with the right tools can we ensure better pathogen and biofilm control while improving the plant quality and health. By combining these various components, pathogens and contaminants can be eliminated and the plant can be enhanced to provide resistance to stresses and better growth and yield.

The Dramm Team is available to consult on and design your water management system. Talk with one of our water management specialists to learn how we can improve your water sanitation and increase plant quality and yield.